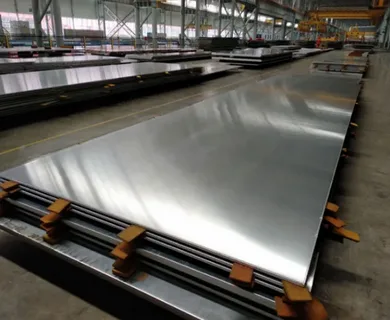

Aluminium plates are widely used in industries such as construction, manufacturing, automotive, and aerospace due to their strength, lightweight nature, and corrosion resistance. However, improper storage and handling can lead to damage, contamination, or safety hazards. Learning how to properly store and handle aluminium plate is essential to maintaining their quality and ensuring workplace safety.

Why Proper Storage and Handling Matter

Aluminium, while durable, is still susceptible to scratches, dents, and corrosion if not managed correctly. Damaged plates can compromise the structural integrity of a project and result in costly replacements. Additionally, mishandling can pose safety risks to workers, making best practices essential in both small workshops and large-scale operations.

Best Practices for Storing Aluminium Plates

1. Keep Plates Dry and Covered

Moisture is the enemy of aluminium. Although the metal forms a natural oxide layer that helps resist rust, prolonged exposure to water can lead to corrosion, especially if contaminants like salt or industrial chemicals are present.

- Store plates indoors in a climate-controlled environment.

- Use waterproof covers or tarps if storage must be done outdoors temporarily.

- Ensure that the storage area is well-ventilated.

2. Use Proper Racking Systems

Flat aluminium plates should never be stacked on bare floors or in a way that promotes warping or bending.

- Use padded, horizontal racks with dividers to prevent metal-to-metal contact.

- Place spacers between stacked plates to allow for airflow and prevent surface scratches.

- Avoid stacking too high, which can cause lower plates to warp or become damaged under pressure.

3. Label and Organize Inventory

To avoid unnecessary handling, label all aluminium plates by size, alloy type, and thickness. Organize them by project use or material specification to reduce time and movement during retrieval.

Safe Handling Techniques

1. Use Proper Lifting Equipment

Aluminium plates can be heavy, especially in large dimensions. Manual lifting may cause injury or damage to the plates.

- Use forklifts, vacuum lifters, or overhead cranes with non-abrasive slings.

- Ensure that lifting tools are rated for the weight of the plates.

- Train workers on safe lifting procedures.

2. Wear Protective Gear

Aluminium edges can be sharp and may cause injuries if handled without care.

- Always wear gloves, safety glasses, and steel-toe boots.

- Use padding when necessary to prevent edge damage.

Regular Maintenance and Inspection

One of the most overlooked aspects of how to properly store and handle aluminium plates is routine inspection. Check storage racks, covers, and lifting equipment regularly to ensure they’re in good condition. Also, inspect plates periodically for signs of corrosion or surface damage and take corrective action if necessary.

Conclusion

Understanding how to properly store and handle aluminium plates is crucial for preserving their quality, ensuring safety, and optimizing workflow. By implementing the right storage systems, handling tools, and safety practices, businesses can reduce waste, avoid delays, and maintain a high standard of material care. Whether you’re managing a small inventory or a large stockpile, following these guidelines will protect your investment and ensure smooth operations.